Energizing India News, 25 Aug 21′

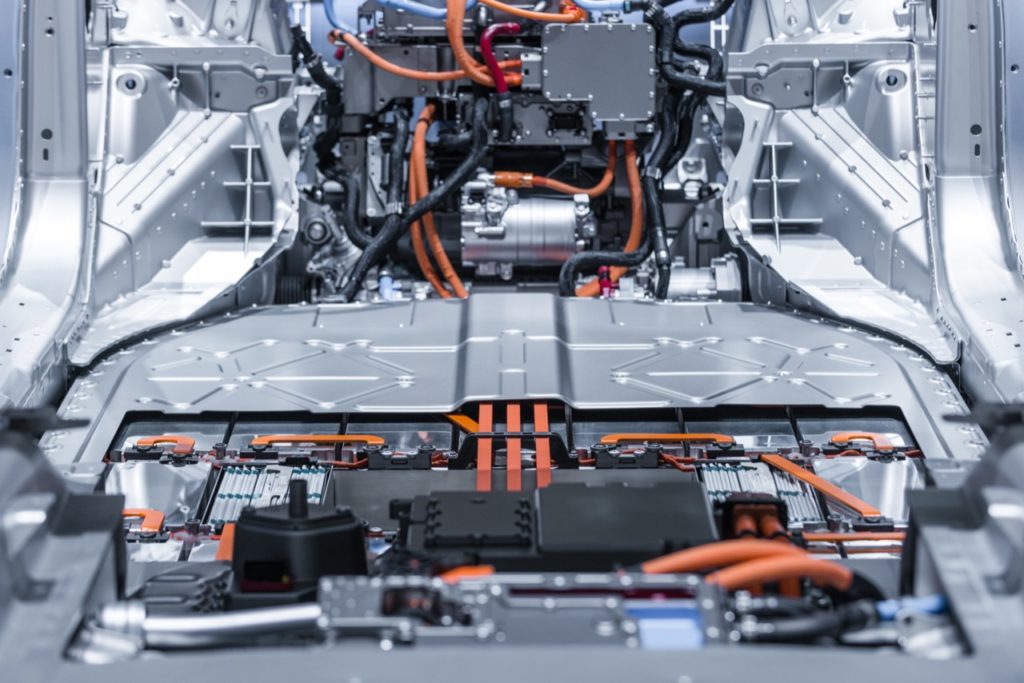

Contemporary Amperex Technology Co. Ltd. or more famously known as CATL, unveiled a sodium-ion battery, a type of lower-density cell that uses cheaper raw materials than batteries made from lithium-ion metals. As well as the first generation of sodium batteries. The Ningde, Fujian-based company also launched a battery-pack solution that can integrate sodium-ion cells and lithium-ion cells into one case, compensating for the energy-density shortage of the former while preserving its advantages.

“Sodium-ion batteries have unique advantages in low-temperature performance, fast charging and environmental adaptability,” CATL Chairman Zeng Yuqun said. “Moreover, they’re compatible and complementary with lithium-ion batteries. Diversified technical routes are an important guarantee for the long-term development of the industry.”

While China’s CATL is the world’s biggest battery maker, supplying Telsa Inc. and selling 34.1- gigawatt-hours in the first half, up 234% year-on-year for a market share of 30%, like other manufacturers it has been hit by rising raw materials costs. The price of lithium carbonate, a core ingredient in most electric vehicle batteries, has doubled this year while the price of nickel, another key metal, is at a five-month high. Research group Fitch Solutions said in a May report that lithium prices will keep trending higher in 2021 and 2022 as demand for lithium-ion batteries accelerates, amid the worldwide shift toward cars that are better for the environment. Tight upstream supply is also expected to keep prices elevated. Outside of their lower raw materials costs, there are abundant sodium resources in the Earth’s crust.

Notwithstanding, CATL said that through breakthroughs in R&D, its first-generation sodium-ion batteries have reached 160 watt-hours/kilogram, a measure of the energy density of energy, and should exceed 200 Wh/kg in coming generations. Zeng, who also founded CATL, said in May that the mass production and industrialization of such cells is still at an early stage. The company called for greater industry deployment around sodium-ion batteries.

In coming decades, hundreds of millions of vehicles will hit the roads, carrying massive batteries inside them and each of those batteries will contain tens of kilos of materials that have yet to be mined. With an increase in the market-share for Lithium-ion in the EV sector, there has been an incremental risk of a shortage in lithium reserves that could end up inflating its prices, which is another addressed concern. Battery- and carmakers are already spending billions of dollars on reducing the costs of manufacturing and recycling Electric Vehicle batteries, spurred in part by government incentives and the expectation of forthcoming regulations. As the world seeks to cut carbon emissions, partly by ramping up Electric Vehicle output, the use of Sodium-ion in manufacturing batteries is seen as the succeeding generation concerning Lithium-ion batteries.

Listen to our podcast with key industry leaders on how we can accelerate the adoption of EVs in India:- https://energizingindia.tv/episodes/

“Sodium-ion batteries have unique advantages in low-temperature performance, fast charging and environmental adaptability”

-CATL Chairman